Our crusher handles soft films, woven bags, hard ABS/PC parts, and thick pipes in one unit. Small models process 50–500 kg/h, industrial units up to 10 tons, running 24/7 with 15–20% higher efficiency to meet demanding production needs.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

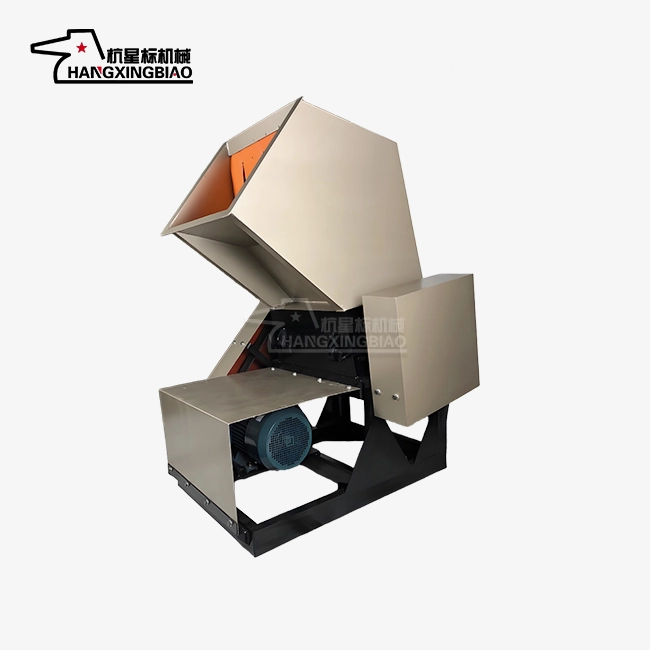

small plastic crusher machine

Small Plastic Crusher Machine: Your Ultimate Solution for Efficient Plastic Recycling

Are you struggling with plastic waste management in your facility? Our small plastic crusher machine delivers exceptional performance for businesses of all sizes. Whether you're running a small workshop or managing industrial operations, this versatile equipment transforms your plastic waste into valuable resources. With processing capacities ranging from 50 to 2000kg/h, our crusher handles everything from soft films to hard plastic components efficiently and reliably.

Why Choose Our Product?

Unmatched Versatility and Performance

Precision Control for Perfect Results

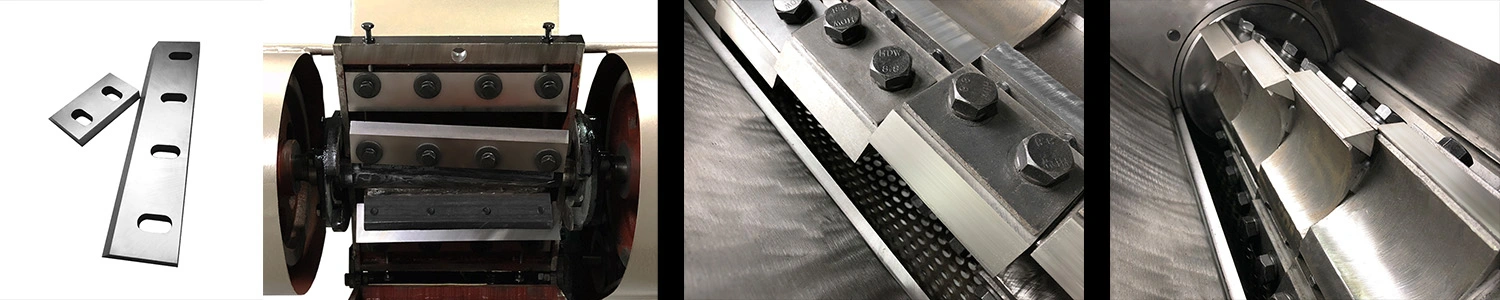

You get complete control over particle size output. By switching screening nets (2-100mm options available), adjusting blade speeds, or changing knife sets, you achieve your exact specifications. Whether you need coarse fragments (5-50mm) for pretreatment or medium particles (2-12mm) for recycling, the uniformity exceeds 90%. No secondary screening required.

Built for Durability and Cost Efficiency

Our premium SKD-11, high-speed steel, and Cr12MoV blades reach HRC55–60 and offer 3000–5000 hours of life. They allow 3–5 regrinding cycles, cutting replacement costs by 60% and keeping maintenance predictable and low.

Immediate Cost Savings Through Recycling

Transform waste into profit instantly. In injection molding and extrusion processes, you can immediately crush waste materials. The crushed output mixes directly with new materials at 3:7 or 5:5 ratios. This increases raw material utilization by 30-50%, saving thousands annually on material procurement costs.

Advanced Safety and Environmental Features

Our enclosed, thick steel design with anti-rebound baffles and safety shields prevents material splash. “Open-and-stop” interlocks cut power when the chamber opens, avoiding injuries. Operating noise stays below 75 dB for safer, quieter workplaces.

Energy Efficient Operation

You'll appreciate the low operating costs of the small plastic crusher machine. Our efficient motor and optimized transmission structure reduce energy consumption by 10-15% compared to traditional equipment. Processing one ton of plastic requires only 8-12 kWh of electricity. Your operational expenses remain competitive while maintaining high productivity.

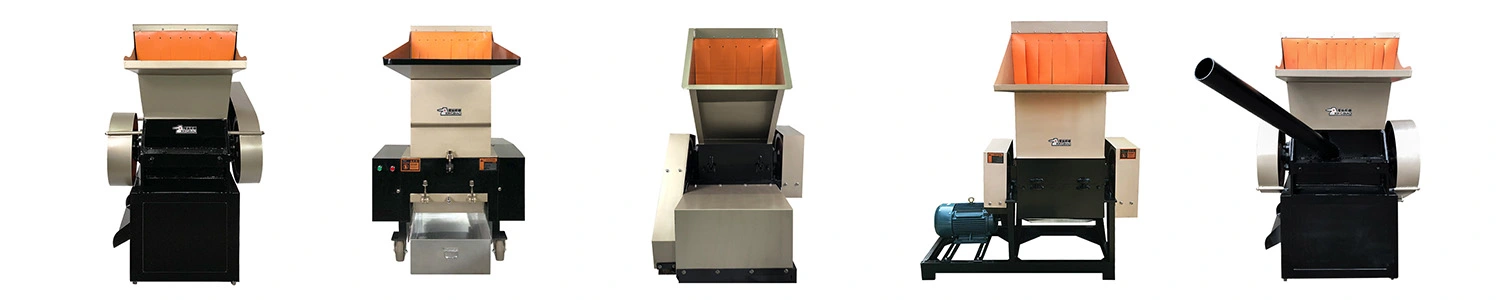

Flexible Configuration Options

Choose from three main configurations based on your needs:

Mobile Units: Small, portable designs with universal wheels. Perfect for moving between different workstations as needed.

Fixed Installation: Medium-sized units for permanent production line integration. Ideal for consistent, high-volume processing.

Integrated Systems: Large units that connect with granulators and conveyor belts. Create complete automated production lines for maximum efficiency.

Easy Maintenance and Operation

Our simple body design enables quick side disassembly for thorough cleaning, ideal when switching plastic colors. With easily accessible maintenance points, inspections and lubrication require no full disassembly, cutting maintenance time by 50% and ensuring smooth operation.

Technical Excellence You Can Trust

Our transmission system uses hardened gears, quality bearings, and optimized lubrication to reduce wear. Dynamic balance testing keeps vibration under 0.1 mm, preventing loosening and lowering failure rates by 40%, ensuring reliable, low-downtime operation.

The product incorporates fully enclosed cavity design that effectively blocks dust leakage. This meets environmental standards for workshops, laboratories, and other sensitive locations where air quality matters.

Comprehensive Support and Service

Ready to transform your plastic waste management? Contact us at postmaster@xingbiaocrusher.com to discuss your specific requirements. Our small plastic crusher machine delivers the reliability, efficiency, and cost-effectiveness your operations demand.

Learn about our latest products and discounts through SMS or email