Process soft films, woven bags, hard ABS/PC plastics, thick pipes, foam, and irregular shapes effortlessly. One machine handles multiple materials without frequent changes or structural adjustments.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

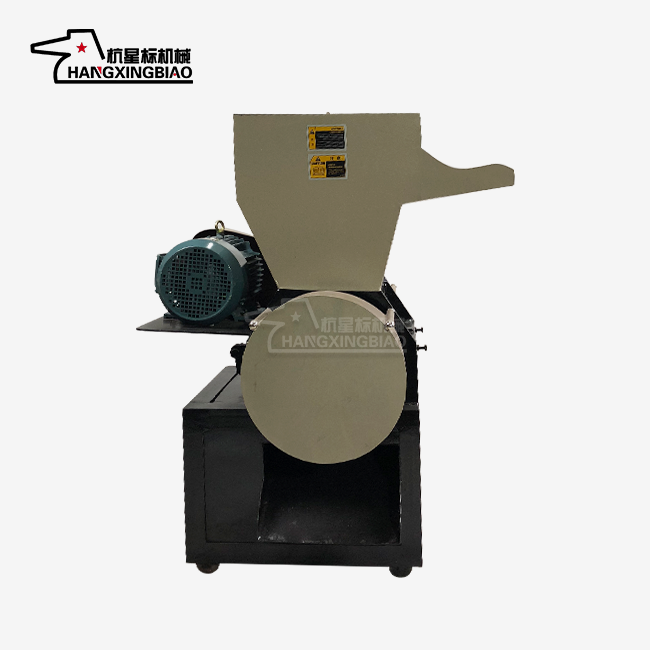

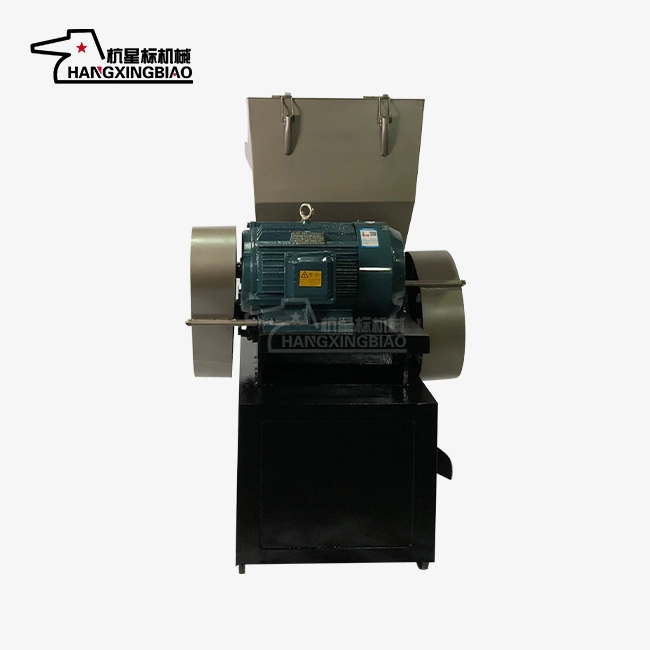

Big plastic crusher machine

Big Plastic Crusher Machine - Industrial Grade Plastic Crushing Solution

Are you looking for reliable plastic waste processing equipment? Our Big plastic crusher machine delivers exceptional performance for industrial recycling operations. With 30 years of specialized experience, Hangzhou Xingbiao Machinery Co., Ltd. has perfected the art of plastic crushing technology. Whether you're processing large plastic parts, thick-walled pipes, or mixed waste materials, this industrial-grade crusher transforms your plastic waste into valuable resources efficiently and cost-effectively.

Why Choose Our Large-Scale Plastic Crushing Solution?

Superior Engineering and Durability

High-strength, stress-relieved steel body resists deformation. SKD-11/D2 and Cr12MoV blades with vacuum and cryogenic treatment offer exceptional hardness, wear resistance, extended life, and 60% lower replacement costs versus carbon steel.

Exceptional Processing Capacity

This Big plastic crusher machine handles diverse materials with impressive efficiency. Small models process 50-500kg per hour, while large industrial units reach 1-10 tons hourly. You can run continuous 24-hour operations without performance degradation.

The unique blade layout and cavity structure design boost crushing efficiency by over 20%. Meanwhile, optimized motor matching reduces energy consumption by 10-15%. Processing one ton of plastic requires only 8-12 kilowatts of electricity.

Versatile Material Compatibility

Advanced Features for Maximum Productivity

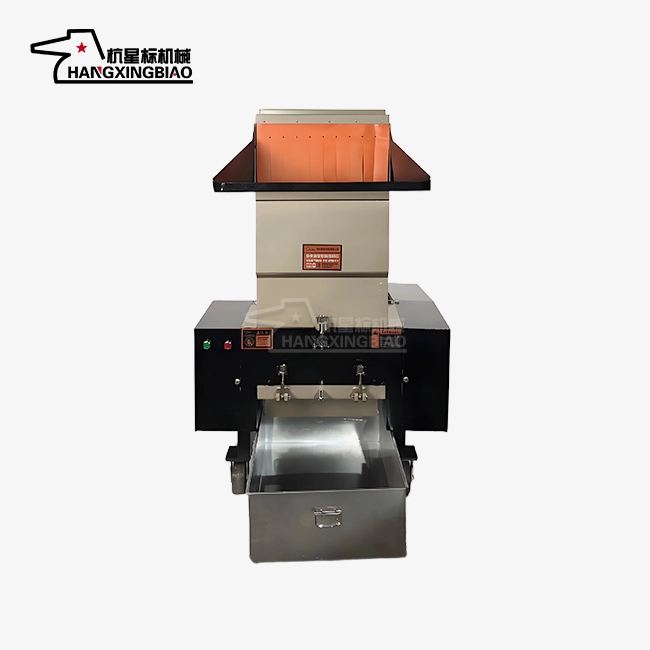

Precision Particle Size Control

Adjust screens (2–100 mm), blade speed, or knives to produce coarse (5–50 mm) or medium (2–12 mm) particles with over 90% uniformity, eliminating secondary screening.

Intelligent Safety Systems

Thick steel chambers with anti-rebound baffles and external shields ensure safety. "Open-and-stop" interlocks automatically cut power when opened, preventing accidental injuries during maintenance or cleaning.

Energy-Efficient Operation

Efficient motors and optimized transmission reduce energy use while maintaining capacity. Precision bearings, hardened gears, and regular lubrication lower wear and failure rates by 40%, keeping operational costs manageable.

Cost-Effective Waste Processing Solution

Immediate Scrap Recycling Benefits

Transform production waste into valuable raw materials instantly. In injection molding and extrusion scenarios, crush nozzle materials and waste scraps immediately. Crushed materials blend with new materials in 3:7 to 5:5 ratios.

Raw material utilization increases 30-50%. Your company saves thousands in procurement costs annually. This Big plastic crusher machine pays for itself through material savings alone.

Low Maintenance Requirements

Simple body design enables quick chamber disassembly. Clean residual materials easily when switching between different colored plastics. This prevents color contamination in your final products.

Key maintenance points like blades and bearings remain accessible. Daily inspection and lubrication require no complete disassembly. Maintenance time reduces by 50% compared to complex alternatives.

Comprehensive Model Range

Choose from mobile units with universal wheels for flexible positioning. Fixed models suit permanent production line installations. Integrated systems link with granulators and conveyors for complete automation.

Coverage spans from laboratory testing (50kg/h) to large recycling facilities (10t/h). Whatever your scale requirements, we provide perfectly matched equipment specifications.

Professional Support and Service

Ready to transform your plastic waste processing efficiency? Contact our experts at postmaster@xingbiaocrusher.com for personalized consultation. Discover how our Big plastic crusher machine revolutionizes your recycling operations with proven industrial-grade reliability.

Learn about our latest products and discounts through SMS or email