Our “shear + impact” dual-effect technology crushes polystyrene without clogging, and the unique blade layout prevents material wrapping. Anti-winding comb teeth ensure smooth foam processing, while the optimized cavity design maintains consistent particle flow throughout operation.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

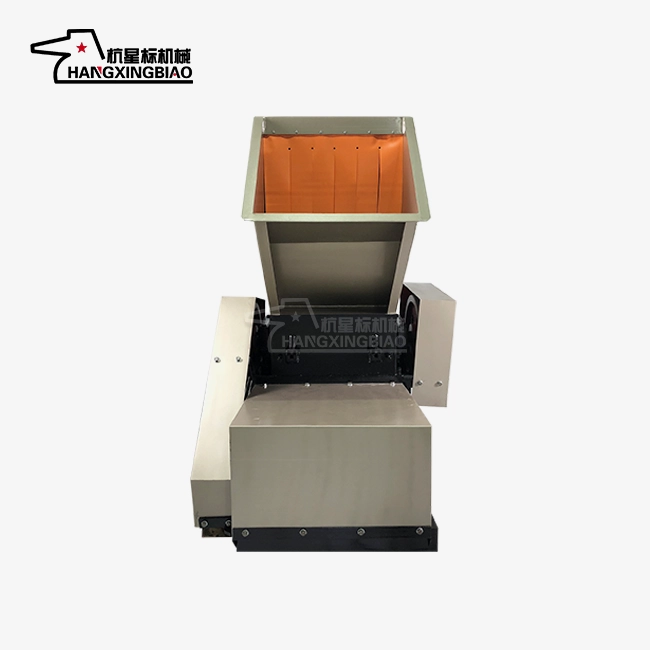

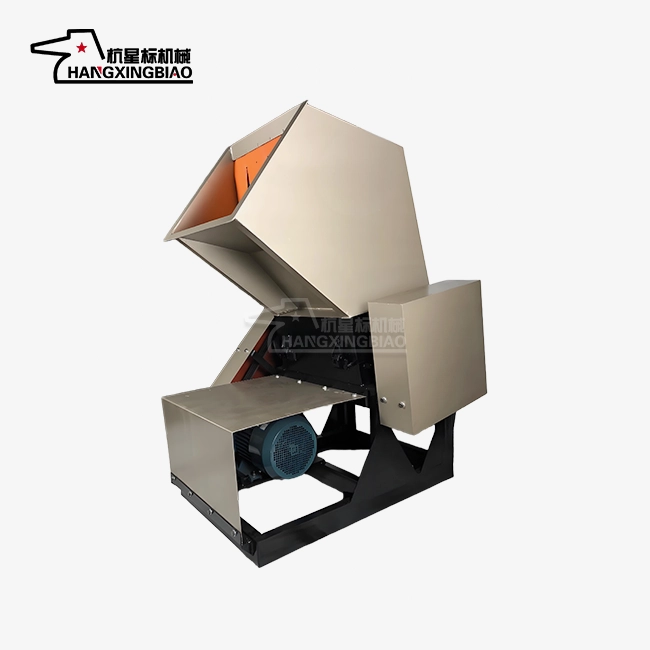

Polystyrene Crusher

Polystyrene Crusher - Professional Plastic Recycling Solution

Are you struggling with polystyrene waste management in your facility? Our Polystyrene Crusher delivers exceptional performance for foam plastic recycling needs. Designed specifically for EPS foam processing, this machine transforms bulky polystyrene waste into manageable particles. Whether you're handling packaging foam, insulation materials, or disposable containers, our crusher provides reliable results. With over 30 years of manufacturing experience, Hangzhou Xingbiao Machinery brings you cutting-edge technology that maximizes efficiency while minimizing operational costs.

Superior Crushing Technology for Foam Materials

The precision-engineered blade spacing accommodates various foam densities. From expanded polystyrene packaging to rigid foam boards, your machine adapts seamlessly to different material types.

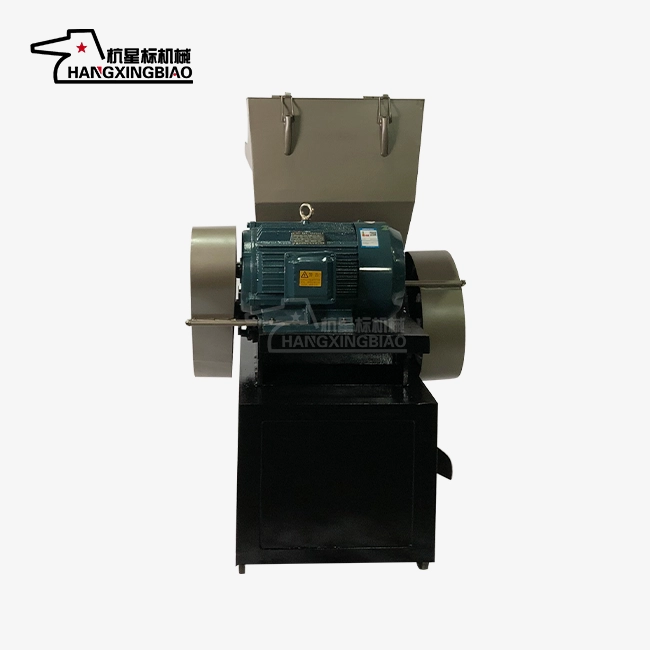

Exceptional Build Quality and Durability

Your investment deserves equipment built to last. Our crusher body uses high-strength steel plates with stress relief treatment. This construction prevents deformation during continuous operation cycles.

The blade system employs SKD-11 and D2 mold steel materials. These premium alloys undergo vacuum heat treatment and cryogenic processing. The result? Exceptional hardness reaching HRC55-60 with outstanding wear resistance.

You can expect blade life exceeding 3,000 operating hours. When maintenance time arrives, the blades support repeated sharpening. This capability reduces your replacement costs by up to 60% compared to standard tools.

Flexible Processing Capabilities

Your production needs vary throughout different projects. Our Polystyrene Crusher accommodates multiple particle size requirements through interchangeable screening systems. Choose from mesh sizes ranging 2mm to 100mm for precise output control.

Processing capacity scales with your operation size. Compact models handle 50-500kg per hour for smaller facilities. Industrial units reach 1-10 tons hourly for large-scale recycling operations.

The uniform particle output exceeds 90% consistency. This precision eliminates secondary screening requirements, saving you time and labor costs.

Energy Efficient Operation

Our optimized motor and transmission cut energy use by 10–15%, requiring only 8–12 kWh per ton of foam. Efficient crushing minimizes heat and prevents melting. With 24-hour operation capability, hardened components and robust bearings ensure reliable performance for high-volume production.

Safety and Maintenance Features

Your team's safety remains our priority. The fully enclosed crushing chamber features thick steel plate construction. Anti-rebound baffles at the feed opening prevent material ejection during operation.

Safety interlocks automatically shut down power when accessing the crushing chamber. This protection system prevents accidental injury during maintenance procedures.

The open-access design simplifies cleaning and maintenance tasks. Key components remain easily accessible for inspection and lubrication. Maintenance time reduces by 50% compared to traditional designs.

Comprehensive Model Range

We offer mobile units with universal wheels or fixed setups for dedicated lines. Integrated systems connect with conveyors and granulators for full recycling lines. Custom configurations are available, with our engineers tailoring solutions to your materials and production volumes.

Proven Manufacturing Excellence

Your success relies on expert-built equipment. Hangzhou Xingbiao Machinery has focused on plastic crushing for 30 years. Our 20 senior engineers work with industry leaders to solve real processing challenges. Strict quality checks, stress tests, and dynamic balancing ensure stable, vibration-free performance.

Complete Support Services

Your investment includes full lifecycle support. Our team guides equipment selection, provides installation and operator training, and offers regular follow-ups to maintain performance. With readily available spare parts, replacements ship quickly, ensuring minimal downtime.

Ready to Transform Your Polystyrene Processing?

Your Polystyrene Crusher solution awaits at Hangzhou Xingbiao Machinery. Contact our experts at postmaster@xingbiaocrusher.com for personalized consultation. We'll help you select the perfect configuration for maximum efficiency and profitability in your recycling operation.

Learn about our latest products and discounts through SMS or email