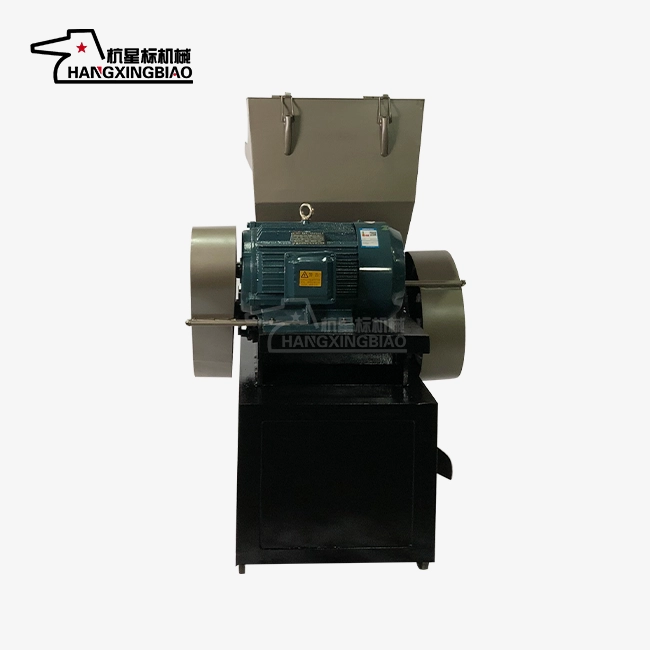

Our crushing equipment uses high-strength steel and SKD-11/D2 or Cr12MoV blades with vacuum heat and cryogenic treatment, ensuring no deformation, high hardness, excellent wear resistance, long service life, lower maintenance, and consistent performance.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

biomass wood crusher

Biomass Wood Crusher: Professional Solution for Sustainable Waste Processing

Are you looking for an efficient way to process biomass waste into valuable resources? Our biomass wood crusher delivers outstanding performance for wood waste processing, agricultural residue crushing, and biomass material preparation. With over 30 years of specialized manufacturing experience at Hangzhou Xingbiao Machinery Co., Ltd., we've perfected crushing technology to help you transform waste into profit while supporting sustainable practices.

Why Choose Our Wood Crushing Solutions?

Superior Engineering and Build Quality

Exceptional Processing Efficiency

Our unique blade layout and cavity structure design increase processing efficiency by over 20% compared to conventional systems. The optimized motor matching reduces energy consumption while maintaining peak performance.

Whether you're processing:

- Wood chips and sawdust

- Agricultural residues like corn stalks

- Tree branches and forestry waste

- Mixed biomass materials

You'll achieve consistent 2-20mm particle output perfect for further processing or direct use.

Versatile Material Compatibility

This equipment handles diverse biomass materials with ease. From soft agricultural residues to hard wood waste, you won't need frequent equipment adjustments or replacements. One machine covers multiple processing scenarios, maximizing your operational flexibility.

Advanced Features for Optimal Performance

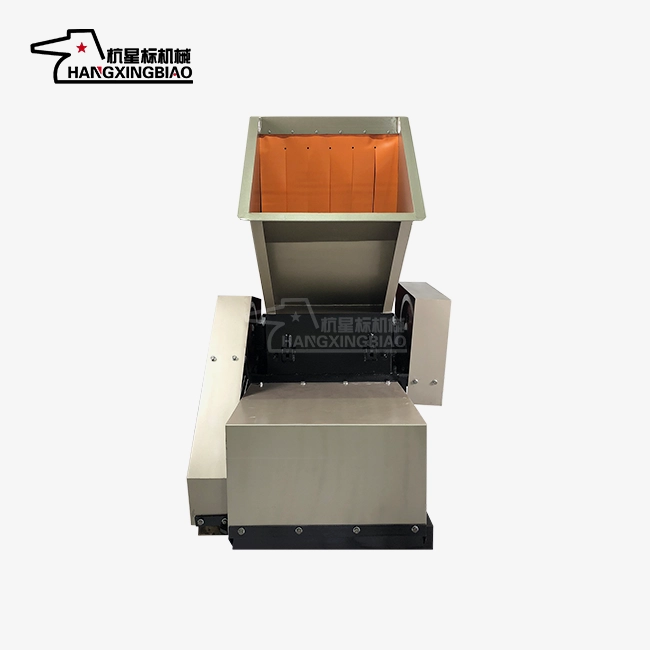

Precise Particle Size Control

You can achieve accurate, controllable particle sizes by changing screening nets with different pore sizes (2-100mm options available). Adjust blade speed or modify the cutting configuration to produce:

- Coarse fragments (5-50mm) for pretreatment applications

- Medium particles (2-12mm) for pelletizing or direct use

- Fine particles for specialized applications

Particle uniformity of the biomass wood crusher exceeds 90%, eliminating secondary screening requirements.

Durable Components, Lower Operating Costs

Our core blade assemblies use premium alloy materials with hardness reaching HRC55-60. For typical biomass processing, blade life extends 3000-5000 hours. The blades support repeated sharpening (3-5 times), reducing replacement costs by 60% compared to standard carbon steel alternatives.

Energy-Efficient Operation

The efficient motor and optimized transmission structure reduce energy consumption by 10-15% compared to traditional equipment. Processing one ton of biomass material requires only 8-12 kWh, keeping your operating costs manageable while maintaining high throughput.

Safety and Reliability Features

Comprehensive Safety Protection

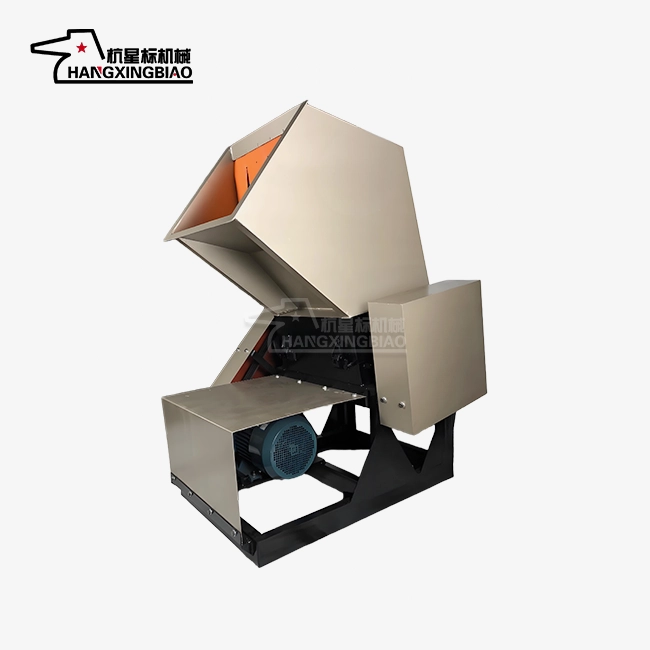

The crushing chamber features thick steel plate welding with anti-rebound baffles at the feed inlet. External safety shields effectively block material splash during operation. Select models include "open-and-stop" interlocking devices that automatically cut power when accessing the chamber.

Stable, Low-Maintenance Operation

Our transmission systems use precision bearings, hardened gears, and optimized lubrication to reduce wear. Key parts pass dynamic balance tests with vibration ≤0.1 mm, preventing loosening and lowering failure rates by 40% compared to standard models.

Flexible Configuration Options

Multiple Model Options

Choose from three main configurations:

- Mobile Units: Compact designs with universal wheels for flexible positioning

- Fixed Installation: Medium-capacity floor-mounted units for permanent production lines

- Integrated Systems: Large-capacity units that link with conveyors and downstream equipment

Processing capacities range from laboratory-scale (50kg/h) to industrial-scale (10t/h), covering all application requirements.

Easy Maintenance and Cleaning

The simple body design allows quick cavity access for thorough cleaning. This proves especially valuable when switching between different biomass types. Key maintenance points remain accessible without full machine disassembly, reducing maintenance time by 50%.

Professional Support and Service

For processing capacity recommendations, technical specifications, or custom configuration discussions, contact our application specialists at postmaster@xingbiaocrusher.com. Let our biomass wood crusher technology help you achieve your sustainability and profitability goals efficiently.

Learn about our latest products and discounts through SMS or email