- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

crusher grinder screen

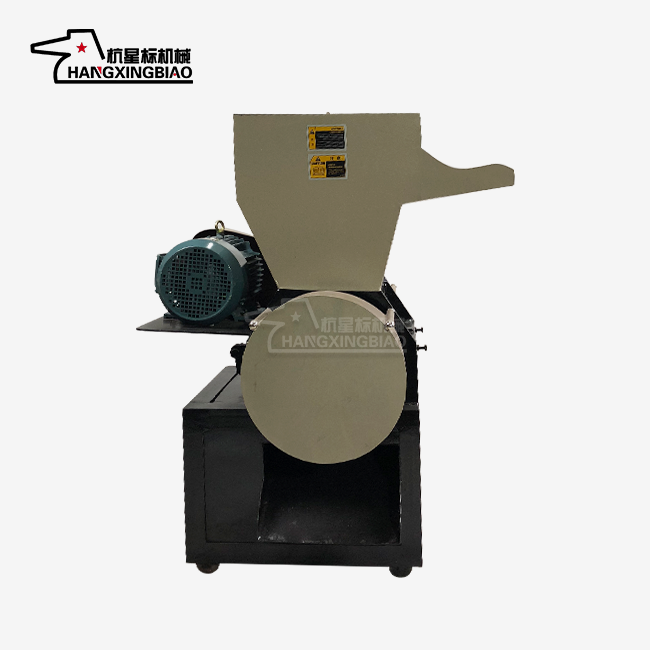

Crusher Grinder Screen: Premium Quality Screening Solutions for Your Processing Needs

Are you looking for reliable screening solutions for your crushing operations? Our high-quality crusher grinder screen delivers exceptional performance and durability for all your material processing requirements. At Hangzhou Xingbiao Machinery Co., Ltd., we understand that the right screen makes all the difference in achieving optimal particle size and production efficiency. With 30 years of expertise, we deliver reliable screening solutions for modern industrial crushing applications.

What Makes Our product Special?

Our precision-engineered screens ensure consistent results through strict quality control. Mesh sizes are tailored to your materials and processing goals. Built for durability, they handle soft plastics, rigid materials, and waste efficiently. Material selection considers corrosion, cleanliness, and environment for optimal screening performance.

Screen Specifications and Material Options

Metal Screen Construction

Our metal screens are primarily manufactured using premium stainless steel wire and high-grade iron wire. These materials provide exceptional strength and longevity in demanding applications.

Key features include:

- High strength construction for heavy-duty applications

- Superior wear resistance for extended service life

- Excellent corrosion resistance in challenging environments

- Precise mesh openings for consistent particle size control

Customization Options

We classify screen specifications according to mesh opening diameter. This classification system helps you select the perfect screen for your specific requirements. Our engineering team works closely with you to determine the optimal mesh size for your materials.

The selection process considers several important factors:

- Material type and characteristics

- Desired output particle size

- Production volume requirements

- Environmental conditions

- Maintenance preferences

Applications and Benefits

Our crusher grinder screen solutions serve diverse industries and applications. From plastic recycling facilities to waste processing operations, our screens deliver reliable performance.

Common applications include:

- Plastic film and bag processing

- Rigid plastic part size reduction

- Pipe and profile material recycling

- Mixed waste stream separation

- Quality control in manufacturing processes

The benefits of choosing our screening solutions extend beyond basic functionality. You'll experience improved production efficiency, reduced downtime, and consistent output quality.

Technical Advantages

Accuracy Engineering

Our screens include absolutely built openings that keep up their shape and measure all through the item lifecycle. This consistency guarantees unsurprising comes about and solid performance.

Easy Establishment and Maintenance

We plan our screens with user-friendly establishment highlights. The quick-change structure minimizes downtime amid screen substitution or support activities.

Durability and Longevity

The strong development and quality materials guarantee amplified benefit life. This strength interprets to lower working costs and decreased substitution frequency.

Quality Assurance and Support

At Hangzhou Xingbiao Machinery, our experienced engineering team ensures top-quality screen design and manufacturing through strict quality control at every production stage.Each crusher grinder screen undergoes comprehensive testing before shipment to ensure it meets our exacting standards.

Comprehensive Service Support

Our commitment extends beyond product delivery. We provide complete support including:

- Technical consultation for screen selection

- Installation guidance and training

- Regular maintenance recommendations

- Prompt response to technical inquiries

- Reliable spare parts availability

Our service team responds to customer inquiries within 24 hours. This rapid response ensures minimal disruption to your operations.

Choosing the Right Screen for Your Application

Selecting the suitable screen requires cautious thought of your particular needs. Our specialized group assesses different variables to suggest the ideal solution.

Selection criteria include:

- Material characteristics and processing requirements

- Environmental factors and operating conditions

- Production volume and efficiency targets

- Maintenance capabilities and preferences

- Budget considerations and lifecycle costs

We work with you to get it these necessities and give custom fitted suggestions. This collaborative approach guarantees you get the most appropriate screening arrangement for your application.

Getting Started

Contact our technical specialists at postmaster@xingbiaocrusher.com to discuss your requirements. We'll provide expert guidance and detailed recommendations based on your unique crusher grinder screen application needs. Let us help you achieve optimal processing results with our proven screening solutions.

Learn about our latest products and discounts through SMS or email