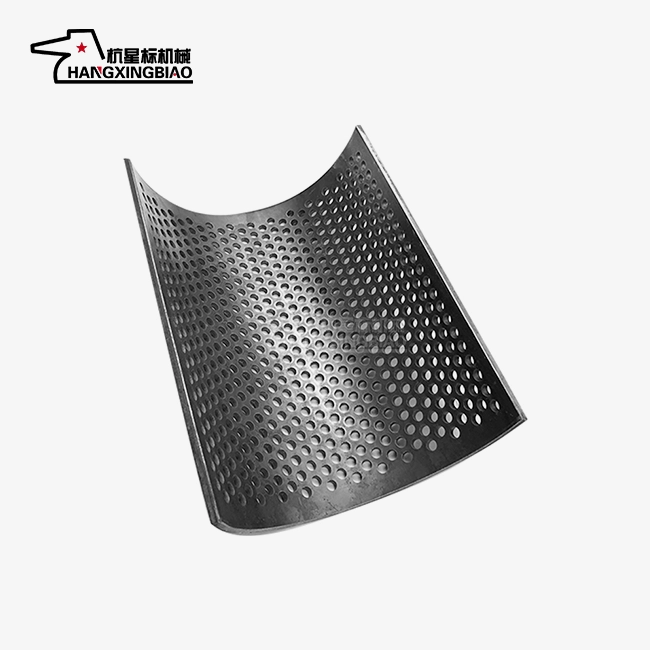

Your crushing success begins with the right material. Using SKD-11 and D2 steels, we match each application for hardness, wear resistance, and superior performance.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Crusher Blade For Plastic

Geometric accuracy: size tolerance, parallelism and verticality of blade shall be strictly controlled to ensure assembly accuracy with crusher and avoid vibration, noise or uneven shearing during operation.

Blade angle: design blade angle according to material characteristics, hard and brittle materials need sharp edge (small angle), tough materials need blunt edge (large angle), balance sharpness and anti-chipping ability.

Heat treatment process: after quenching, tempering and other treatments to ensure uniform hardness of the blade, while reducing internal stress, to prevent deformation or fracture in use.

Surface treatment: some blades will be nitrided, chrome plating and other surface treatment, enhance wear resistance and rust resistance, extend service life.

Professional Crusher Blade For Plastic - Premium Quality & Long-Lasting Performance

When it comes to plastic recycling equipment, selecting the right Crusher Blade For Plastic makes all the difference. At Hangzhou Xingbiao Machinery Co., Ltd., we specialize in manufacturing high-performance blades that deliver exceptional cutting precision and durability. Our 30-year expertise in plastic crusher technology ensures you get blades designed specifically for your crushing needs, maximizing efficiency while minimizing downtime.

Why Choose Our Plastic Crusher Blades?

Superior Material Selection

Accuracy Fabricating Process

Each edge meets strict geometric measures for exactness, guaranteeing idealize fit with your crusher hardware. Exact resiliences avoid vibration and clamor, conveying smooth, calm operation and reliable cutting execution all through the blade’s lifespan.

Advanced Warm Treatment Technology

Our progressed warm treatment guarantees uniform hardness and moo inner push, making edges safe to misshapening and breaking. This handle conveys amplified benefit life and dependable execution, setting our quality separated from competitors.

Optimized Edge Angles

Our engineers optimize edge points for each fabric, adjusting sharpness and toughness to maximize cutting proficiency and avoid untimely failure.

Enhanced Surface Treatments

Nitriding or chrome plating upgrades edge toughness, diminishing upkeep and costs whereas amplifying benefit life and boosting efficiency in requesting situations.

Complete Product Range for Every Need

Heavy-Duty Blades

Our heavy-duty blades cut large plastic parts with ease, enduring high impact loads while maintaining sharp, reliable edges for tough applications.

High-Precision Blades

For applications requiring fine particle sizes, our precision blades deliver consistent results. These blades work perfectly in centralized feeding systems and automated recycling lines.

Specialized Film Blades

Soft plastics like films and woven bags present unique challenges. Our specialized blade designs prevent material entanglement while ensuring clean cuts. You'll eliminate frustrating jams and blockages.

Custom Solutions

We design custom blades to meet your unique processing needs, enhancing crusher performance through tailored solutions and close collaboration.

Our Commitment to Quality Excellence

Research and Development Excellence

Our 20 senior engineers drive continuous blade innovation, partnering with industry leaders to solve real-world challenges and deliver cutting-edge technology.Our Crusher Blade For Plastic incorporates the latest metallurgical innovations and design improvements.

Rigorous Quality Control

Every blade undergoes comprehensive testing before shipment. We verify hardness, dimensional accuracy, and surface finish to ensure consistent quality. This attention to detail guarantees reliable performance in your operations.

Comprehensive Support Services

Choosing the right blades is simple with our expert support. We analyze your materials and goals, provide installation guidance, and train your operators to ensure proper handling, alignment, and maintenance for maximum blade life and performance.

Technical Specifications and Options

Material Grades Available

- SKD-11 tool steel for general applications

- D2 steel for high-wear environments

- Cr12MoV for specialized requirements

- Custom alloys for unique applications

Surface Treatment Options

- Standard heat treatment

- Nitriding for enhanced wear resistance

- Chrome plating for corrosion protection

- Specialized coatings for specific environments

Dimensional Capabilities

We manufacture blades in various sizes and configurations. Standard dimensions cover most crusher models, while custom sizing accommodates specialized equipment requirements.

Maximizing Your Blade Investment

Proper Installation

Correct blade installation ensures optimal performance. Follow torque specifications and alignment procedures carefully. Proper installation prevents premature wear and safety issues.

Regular Maintenance

Simple maintenance practices significantly extend blade life. Keep blades clean and inspect them regularly for wear or damage. Replace worn blades promptly to maintain cutting efficiency.

Operating Best Practices

Feed materials consistently to avoid shock loads. Remove metal contaminants that can damage cutting edges. Monitor cutting performance and adjust feed rates as needed.

Ready to Upgrade Your Crusher Performance?

Contact our technical team today for personalized Crusher Blade For Plastic recommendations. Email us at postmaster@xingbiaocrusher.com to discuss your specific requirements. Let our three decades of expertise help you achieve superior crushing performance.

Learn about our latest products and discounts through SMS or email