We manage each edge generation organize, guaranteeing strict quality control from materials to last assessment. Stress-relief medicines avoid twisting, and high-strength materials guarantee dependable, steady execution beneath requesting conditions.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

plastic crusher blade

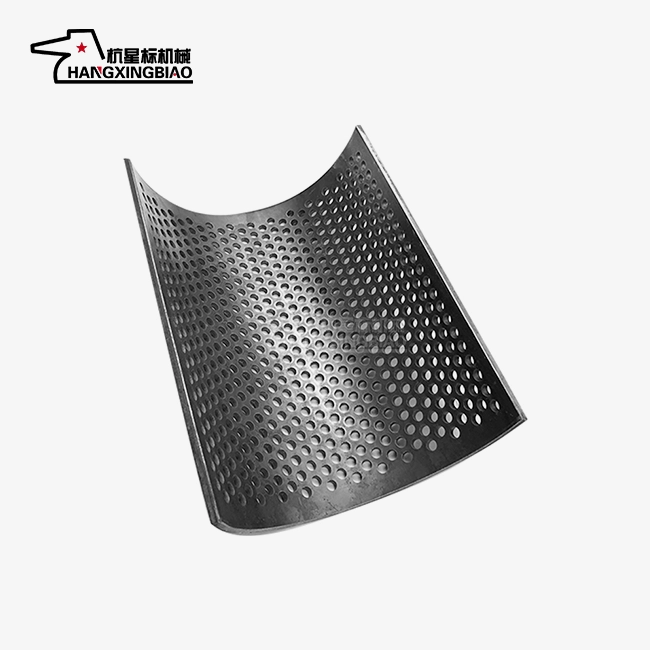

Geometric accuracy: size tolerance, parallelism and verticality of blade shall be strictly controlled to ensure assembly accuracy with crusher and avoid vibration, noise or uneven shearing during operation.

Blade angle: design blade angle according to material characteristics, hard and brittle materials need sharp edge (small angle), tough materials need blunt edge (large angle), balance sharpness and anti-chipping ability.

Heat treatment process: after quenching, tempering and other treatments to ensure uniform hardness of the blade, while reducing internal stress, to prevent deformation or fracture in use.

Surface treatment: some blades will be nitrided, chrome plating and other surface treatment, enhance wear resistance and rust resistance, extend service life.

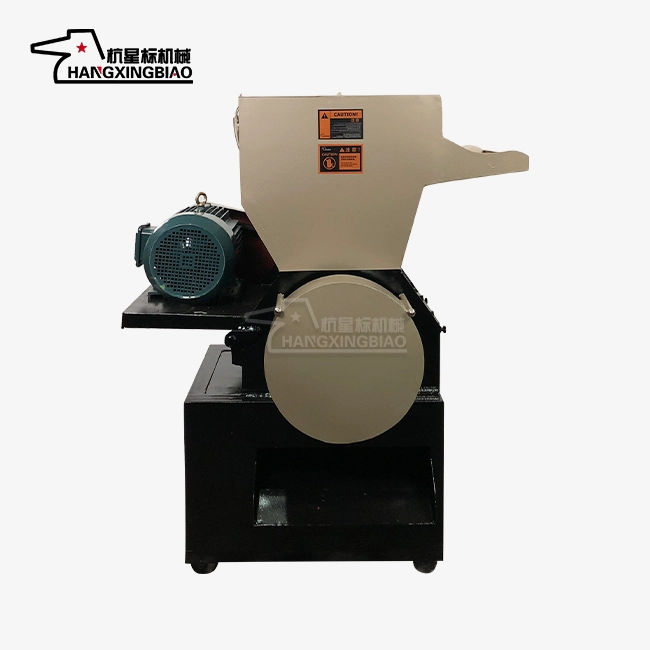

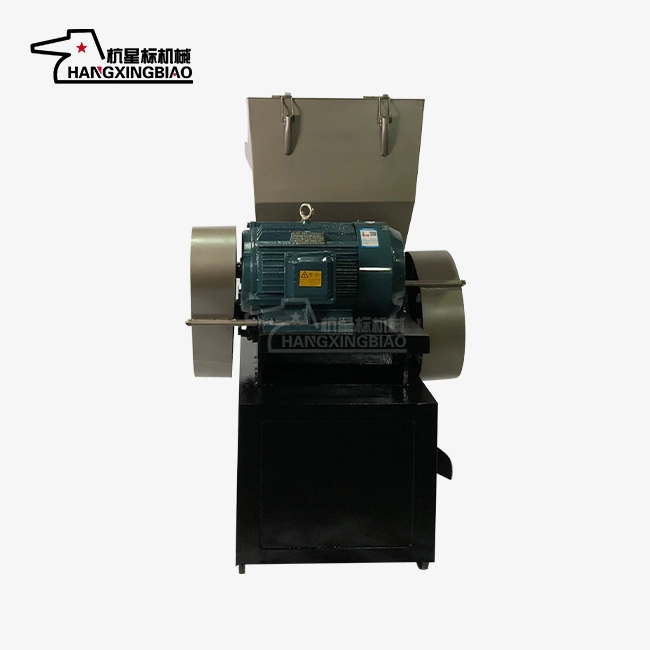

Premium Plastic Crusher Blade for Superior Crushing Performance

When your plastic processing operation demands reliable performance, choosing the right plastic crusher blade becomes critical for your productivity and profitability. At Hangzhou Xingbiao Machinery Co., Ltd., we understand that every crushing application is unique. That's why we've dedicated 30 years to perfecting our blade technology. Our specialized focus on crusher development has made us a trusted partner for companies worldwide who need consistent, high-quality crushing results.

Why Material Selection Matters for Your Crushing Success

Your crushing efficiency depends heavily on blade material choice. We select materials based on your specific plastic types and operating conditions. Hard materials like SKD-11 and D2 mold steel offer exceptional durability for tough applications. Softer materials work better for flexible plastics that might otherwise cause premature wear.

The hardness, wear resistance, and affect quality of your edges straightforwardly influence your operational costs. When you select the off-base fabric, you'll confront visit substitutions and unforeseen downtime. Our building group assesses your materials to suggest the ideal edge composition for your needs.

Precision Engineering That Delivers Results

Geometric accuracy separates professional-grade blades from standard options. We maintain strict dimensional tolerances, parallelism, and perpendicularity standards during manufacturing. This precision ensures perfect assembly with your crusher and eliminates vibration, noise, and uneven cutting.

Blade angle design requires careful consideration of material characteristics. Hard, brittle plastics need sharper cutting edges with smaller angles. Tough, flexible materials perform better with blunter edges and larger angles. Our design team balances sharpness with chip resistance to maximize your blade life.

Advanced Heat Treatment for Long-Lasting Performance

Our warm treatment prepare sets our edges separated from competitors. Through controlled extinguishing and treating, we accomplish uniform hardness all through the edge structure. This handle diminishes inside push that may cause misshapening or breaks amid overwhelming use.

The vacuum heat treatment and deep cryogenic processing we employ create a more stable molecular structure. Your plastic crusher blade maintains its cutting edge longer and resists wear even under demanding conditions.

Surface Treatments That Extend Service Life

Surface enhancement technologies like nitriding and chrome plating add extra protection to your investment. These treatments create harder surface layers that resist wear and corrosion. You'll notice extended intervals between blade changes and more consistent crushing performance.

The enhanced wear resistance translates directly to lower operating costs. When your blades last longer, you spend less time on maintenance and more time on productive crushing operations.

Custom Solutions for Unique Applications

Every plastic processing operation faces different challenges. Film processors need blades that prevent material wrapping. Rigid plastic recyclers require maximum impact resistance. Medical waste processors need blades that maintain sterile conditions.

Our 20-person engineering team works with you to develop custom blade solutions. We've partnered with major companies to solve specific crushing challenges. Your unique requirements get the attention they deserve.

Quality Assurance You Can Trust

Installation and Maintenance Support

Proper installation ensures blade performance and safety. Our technical team provides detailed guidance and maintenance training. Regular maintenance schedules and tailored recommendations help predict replacement needs, preventing unexpected failures and extending blade life.

Getting Started with Your Blade Solution

For technical consultation and quotes, reach out to our team at postmaster@xingbiaocrusher.com. Let us show you how the right plastic crusher blade selection can transform your crushing operation's efficiency and profitability.

Learn about our latest products and discounts through SMS or email