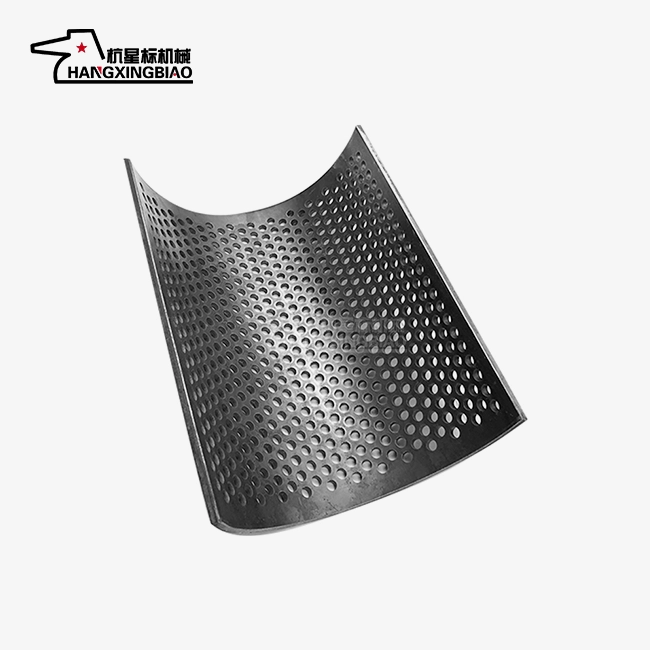

Selecting the right screen is key to quality and efficiency. Mesh size defines particle output, depending on material type—soft films need finer meshes, while hard plastics suit larger ones. Screen durability and flexibility should match production volume for consistent, efficient performance.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Plastic crusher screen

Plastic Crusher Screen - Precision Components for Optimal Shredding Performance

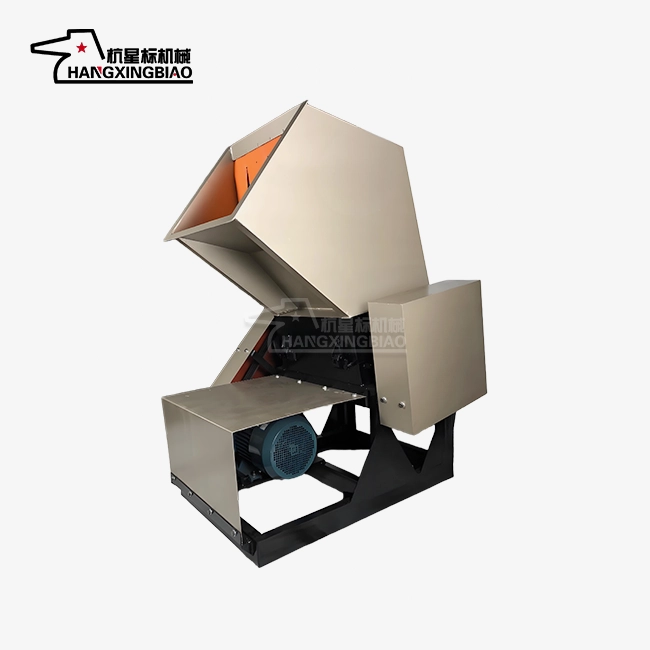

When you're looking for reliable plastic processing solutions, the plastic crusher screen plays a crucial role in determining your output quality and efficiency. At Hangzhou Xingbiao Machinery Co., Ltd., we understand that the right screen can make the difference between smooth operations and costly downtime. Our high-quality product components are engineered to deliver consistent performance while meeting your specific material processing requirements. With 30 years of specialized focus on plastic crushing technology, we've perfected every aspect of screen design and manufacturing.

Why Screen Selection Matters for Your Operations

Material Construction and Durability Features

Our screens use premium stainless steel or iron wire for strength and durability. Stainless steel offers corrosion resistance for moisture or chemical environments, while iron wire provides cost-effective reliability for standard uses. Each screen is precisely manufactured and inspected to ensure consistent, long-lasting performance in demanding operations.

Screen Specifications and Sizing Options

Screen specifications follow industry standards for mesh diameter classification. You can select from various opening sizes based on your specific needs. Common sizes range from fine mesh for detailed sorting to larger openings for preliminary processing.

The plastic crusher screen opening size directly affects your final product characteristics. Smaller openings create finer particles but may reduce throughput speed. Larger openings increase processing speed while producing coarser output.

We offer custom sizing options for specialized applications. Your unique requirements might call for non-standard specifications. Our engineering team can develop screens that match your exact needs.

Proper sizing ensures optimal machine performance. Oversized openings waste energy and reduce quality. Undersized openings create unnecessary resistance and slow production.

Installation and Maintenance Considerations

Our quick-change screen design reduces downtime and keeps production efficient. Easy access allows fast cleaning and maintenance, extending screen life. Proper installation guided by our experts ensures top performance. Keeping spare screens ready provides flexibility for different materials and uninterrupted operation.

Performance Benefits and Efficiency Gains

Quality screens contribute to overall system efficiency improvements. Our unique design features increase crushing efficiency by more than 20%. The optimized construction reduces energy consumption while maintaining high output rates.

Consistent particle sizing improves your downstream processing operations. Uniform material feeds better into subsequent equipment. This consistency reduces waste and improves final product quality.

The robust construction minimizes replacement frequency. Longer screen life reduces operating costs and maintenance requirements. Your investment delivers sustained value over extended operating periods.

Quality Assurance and Support Services

Every product undergoes rigorous quality testing before shipment. Our 20-member engineering team ensures each component meets strict performance standards. This commitment to quality reflects our 30 years of specialized experience.

We maintain comprehensive inventory levels for quick delivery. Standard sizes ship immediately from stock. Custom specifications typically complete within reasonable timeframes based on complexity.

Technical support continues throughout your screen's service life. Our engineers provide application guidance and troubleshooting assistance. This ongoing support helps optimize your crushing operations.

Getting the Right Screen for Your Application

Quality screens represent a smart investment in your processing capabilities. The right plastic crusher screen delivers consistent performance while reducing overall operating costs. Contact our team at postmaster@xingbiaocrusher.com for expert guidance on selecting the perfect screen solution for your plastic crushing applications.

Learn about our latest products and discounts through SMS or email