High-Performance Plastic Crusher Cutting Blades for Maximum Efficiency

When your plastic processing operations demand precision and durability, Plastic Crusher Cutting Blades from Hangzhou Xingbiao Machinery Co., Ltd. deliver exceptional performance. Our cutting edges are built with 30 a long time of specialized ability in plastic pulverizing innovation. Each edge experiences thorough quality control and exactness fabricating forms. You get prevalent cutting execution that maximizes your generation effectiveness whereas minimizing downtime and upkeep costs.

Why Our Cutting Blades Outperform the Competition

Premium Material Selection

We utilize premium SKD-11/D2 and Cr12MoV steels for predominant hardness and wear resistance. Our engineers analyze your pulverizing necessities to suggest the perfect fabric, guaranteeing enduring sharpness and ideal execution for each application.

Advanced Warm Treatment Technology

Each edge experiences vacuum warm treatment and cryogenic preparing for uniform hardness, strength, and soundness. Extinguishing and hardening expel inner stretch, avoiding misshapening and guaranteeing steady, long-lasting cutting execution in requesting operations.

Precision Geometric Engineering

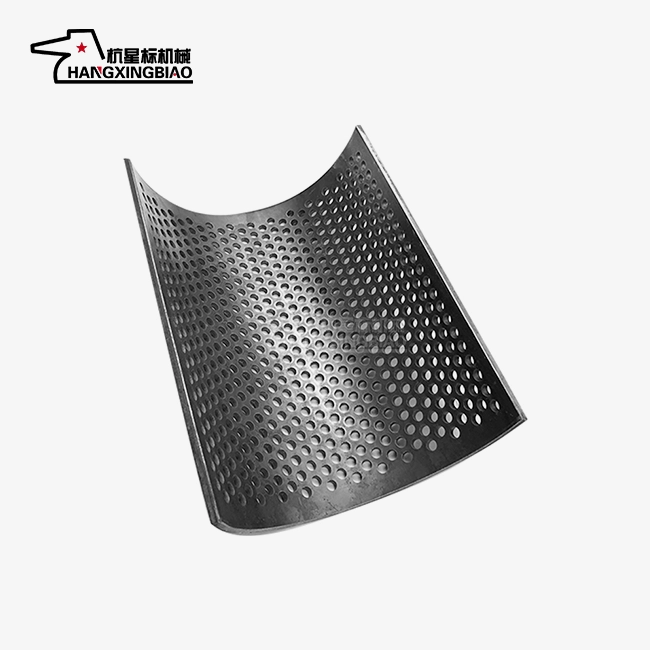

Dimensional accuracy matters for crusher performance. We maintain strict tolerances on parallelism and perpendicularity during manufacturing. Proper blade geometry eliminates vibration and noise while ensuring smooth operation.

Our Plastic Crusher Cutting Blades feature carefully calculated blade angles. Sharp-edged designs work best for brittle materials, while blunt edges handle tough, flexible plastics effectively. This engineering balance maximizes cutting efficiency while preventing premature edge chipping.

Custom Blade Solutions for Every Application

Heavy-Duty Industrial Blades

Large plastic components require robust cutting solutions. Our heavy-duty blades handle thick pipes, profiles, and die head materials with ease. The reinforced design withstands high-impact crushing without blade damage.

Specialized Film and Fiber Blades

Soft plastic films and fibers present unique crushing challenges. Our specialized blade geometry prevents material entanglement while delivering clean cuts. You achieve consistent particle size without production slowdowns.

High-Efficiency Energy-Saving Design

The unique blade layout increases crushing efficiency by over 20%. Optimized cutting angles reduce motor load, lowering your energy consumption. You save on operational costs while boosting productivity.

Superior Surface Treatments for Extended Life

Advanced Coating Technologies

Selected blades receive nitriding or chrome plating treatments. These surface enhancements dramatically improve wear resistance and corrosion protection. Your blades maintain cutting performance in demanding industrial environments.

Easy Maintenance Features

Quick-change blade systems minimize replacement time. The open design allows easy cleaning and inspection. You spend less time on maintenance and more time on productive operations.

Quality Assurance You Can Trust

Our master group guarantees each edge meets strict guidelines through progressed R&D associations. Each bunch is tried for hardness, accuracy, and cutting execution, ensuring dependable, high-quality edges for your operations.

Application Versatility

Our versatile edges handle PVC, movies, elastic, and blended plastics with ease. Measured plans permit speedy component substitution, keeping up best execution whereas diminishing upkeep costs and by and large proprietorship expenses.

Professional Back and Service

Our specialized group analyzes your materials and crusher specs to suggest ideal edges. We give establishment back, support preparing, and progressing meetings to upgrade execution, expand edge life, and maximize your venture.

Getting Started with Premium Cutting Blades

Contact our engineering team at postmaster@xingbiaocrusher.com to discuss your blade requirements. We provide detailed specifications, performance projections, and pricing for your custom Plastic Crusher Cutting Blades solution. Your path to superior crushing performance starts with professional blade selection.