- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

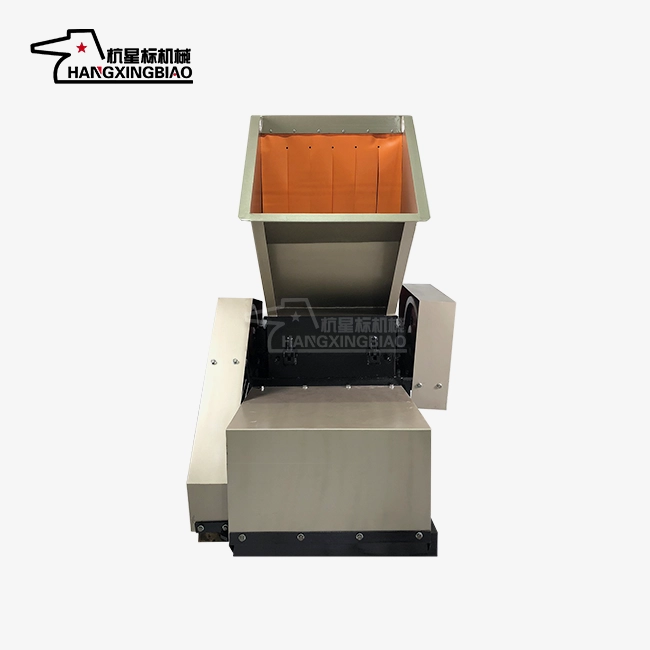

Plastic Crusher vs Powerful Crusher: Which Fits Your Factory Needs?

Choosing between a plastic crusher and a powerful crusher represents one of the most critical equipment decisions facing manufacturing and recycling facilities today. Although the basic function of both devices is to reduce the size of materials, their design philosophies, processing capacities, and ideal uses are very different. While powerful crushers provide reliable performance across a variety of material types with improved torque and capacity, plastic crushers usually specialize in processing polymeric materials with accuracy and efficiency. When matching equipment capabilities to your unique operational requirements, production volumes, and material characteristics, it becomes crucial to comprehend these differences. This thorough guide explores the main distinctions between various crusher types, assisting you in determining which option best suits the particular requirements and long-term goals of your factory.

What Makes a Plastic Crusher Different from Other Crushing Equipment?

The plastic crusher's specialist engineering, which tackles the particular difficulties of processing polymeric materials, sets it apart from other crushing equipment. A plastic crusher uses an advanced "shear plus impact" double-effect crushing technique that produces clean cuts without producing undesired powder or producing excessive heat, in contrast to crushers made for rocks or minerals that largely rely on compression forces. When working with thermoplastic polymers, which can melt or deform when subjected to high friction, this dual-action system is crucial. In order to maintain material integrity and achieve uniformity above 90% without the need for extra screening processes, the cavity structure is adjusted and the knife group spacing is carefully calculated to assure discharge particles larger than 2mm.

Material-Specific Processing Capabilities

The plastic crusher excels at processing materials that would prove challenging or impossible for general crushing equipment. Thin films that would simply fold and wrap in a powerful crusher get cleanly sheared into uniform flakes by the plastic crusher's optimized blade geometry. Hollow products like bottles and containers that could bounce around ineffectively in compression-type crushers receive decisive cutting action that reduces them to consistent particle sizes. Even reinforced plastics containing fiberglass or fabric reinforcement process smoothly through the anti-winding design, whereas these materials would quickly jam conventional equipment. This material versatility within the polymeric realm justifies the plastic crusher's specialized engineering and typically higher initial cost compared to basic powerful crushers.

Particle Size Control and Uniformity

Achieving consistent particle size distribution matters enormously in downstream processing operations, and plastic crushers deliver superior uniformity compared to many powerful crushers. The combination of screen mesh selection and optimized cutting action produces remarkably consistent discharge materials with over 90% uniformity, eliminating the time and expense of secondary screening. Powerful crushers, while capable of processing diverse materials, often generate wider particle size distributions with more fines and oversized pieces that require additional classification. For operations feeding crushed plastic directly into washing systems, pelletizing lines, or molding processes, the plastic crusher's superior uniformity translates directly into improved efficiency and reduced waste throughout subsequent processing stages.

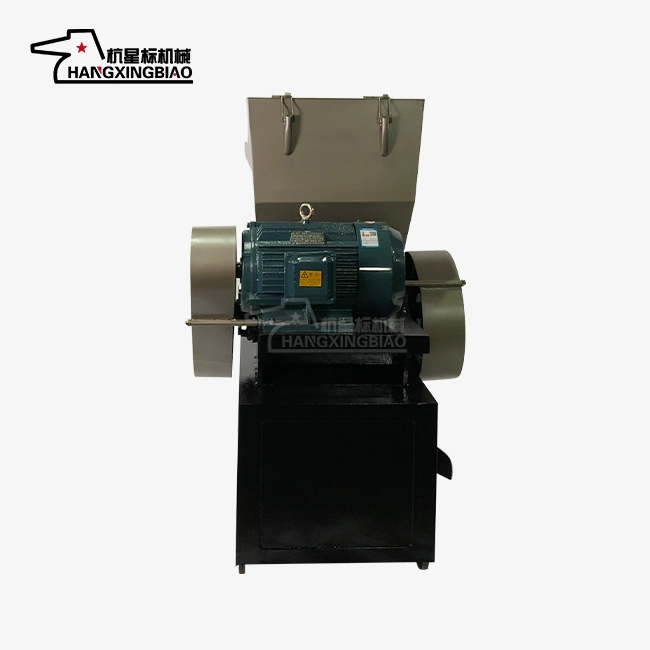

How Do Powerful Crushers Handle Diverse Materials Compared to Plastic Crushers?

Because they can process a remarkable wide range of materials, not just plastics, strong crushers stand out as valuable multipurpose equipment in facilities that handle a variety of waste streams. While a plastic crusher concentrates on polymeric materials, a strong crusher uses robust construction and high-torque motor systems that can handle anything from hard plastics and wood blocks to rubber components and even some metal-contaminated materials. Heavy-duty cutting systems, reinforced structural design, and motor configurations that deliver steady power under various load scenarios are the causes of this adaptability. Facilities handling mixed industrial waste, demolition debris, or changeable recycling streams notably benefit from the strong crusher's adaptability, which removes the need for multiple specialized pieces of equipment.

Heavy-Duty Applications and Extreme Materials

Strong crushers do tasks that would be too much for specialized plastic crushers, such as processing dense plastic parts that need a lot of cutting force, thick-walled containers, and large-diameter pipes. In order to meet the demands of these demanding applications, heavy-duty models have strengthened drive trains that can handle shock loads from irregular items, hydraulic rams that force recalcitrant materials through cutting chambers, and wider feed holes that can accommodate bulky items without pre-sizing. In order to sustain throughput without equipment damage or excessive downtime, facilities processing industrial scrap, such as rejected molded parts, thick-walled drums, and big plastic components, rely on strong crushers. This capability to handle extreme materials justifies the powerful crusher's robust construction and higher operational weight compared to standard plastic crushers.

Centralized Feeding System Integration

High-power, powerful crushers made especially for centralized feeding systems in extrusion and injection molding plants show how unique layouts meet specific operating needs. These machines may be placed directly next to molding machines without disturbing employees or breaking noise rules because of their low-noise operation, which is crucial in production settings. Continuous streams of sprues, runners, and edge trim produced during manufacturing are processed by high-power motors, instantly reintroducing this precious material into the production cycle. The robust crusher is perfect for these demanding beside-the-press applications where downtime has a direct influence on production output and profitability since it can tolerate prolonged high-volume throughput without overheating or performance degradation.

Customization for Unique Challenges

The flexibility of powerful crusher platforms enables customization addressing unique processing challenges that standard equipment cannot handle effectively. Facilities dealing with highly entangled waste materials like tire recycling or large trash container processing benefit from customized powerful crushers featuring modified feed systems, specialized blade configurations, and enhanced anti-jamming mechanisms. This customization capability distinguishes powerful crushers from plastic crushers that typically offer limited configuration options within their specialized design parameters. Operations with unusual material characteristics or non-standard processing requirements often find that only powerful crushers provide the adaptability necessary to develop effective solutions.

Which Crusher Type Offers Better Value for Your Specific Production Requirements?

To find out which type of crusher gives you the best value, you need to look at your individual operational characteristics instead of just assuming that one type is always better than the other. Facilities that mostly or only process plastic materials usually find that specialist plastic crushers work best for their demands in terms of performance and efficiency. The plastic crusher's improved design for polymeric materials makes cleaner cuts, more uniform particles, and no more jamming problems that happen with general-purpose tools while cutting films and fibers. When plastic materials make up most of your waste stream or manufacturing debris, this specialization leads to more throughput, less downtime, and lower operating costs. Investing in a plastic crusher made for a specific purpose pays off in the form of lower maintenance costs and more efficient operations.

Long-Term Operational Cost Analysis

Evaluating total cost of ownership over equipment lifespan provides more accurate value comparison than focusing solely on purchase price. Plastic crushers typically offer lower energy consumption when processing polymeric materials due to optimized blade designs requiring less cutting force. Blade replacement costs vary significantly between crusher types, with plastic crusher blades often lasting longer when used within their designed material range but potentially wearing faster if subjected to abrasive materials. Powerful crushers' heavy-duty components command higher replacement costs but deliver extended service intervals. Comprehensive analysis including energy, maintenance, blade replacement, and downtime costs reveals the true economic picture guiding optimal equipment selection.

Matching Equipment to Material Characteristics

Physical properties of your predominant materials should heavily influence crusher selection. Soft, flexible plastics including films, bags, and foams demand the anti-winding capabilities that plastic crushers provide, as these materials cause endless problems in conventional powerful crushers. Hard, rigid plastics like PVC pipes, HDPE containers, and engineering plastic parts process effectively in either crusher type, though plastic crushers may deliver superior particle uniformity. Mixed materials containing plastics alongside contaminants require the robust construction and tolerance of powerful crushers that handle unexpected items without damage. Matching crusher design to actual material characteristics ensures reliable operation and optimal processing results.

Facility Integration and Operational Workflow

Consider how selected equipment integrates into your overall production or recycling workflow. Facilities with dedicated plastic recycling lines benefit from plastic crushers' specialized capabilities and consistent output feeding downstream washing, pelletizing, or compounding operations. Manufacturing plants generating production scrap alongside finished goods may find powerful crushers' versatility enables processing of packaging materials, wood pallets, and other ancillary waste streams through the same equipment handling production plastic scrap. The operational simplicity of single-machine processing versus managing multiple specialized crushers often proves decisive in equipment selection, particularly in facilities with limited floor space or labor resources.

Conclusion

Choosing between plastic crushers and powerful crushers ultimately depends on your facility's specific material composition, processing volume, and operational requirements rather than assuming one type universally surpasses the other. Plastic crushers excel when processing predominantly polymeric materials, delivering superior particle uniformity, anti-winding capabilities, and specialized performance that justifies their focused design. Powerful crushers provide exceptional versatility across diverse material types, robust construction for demanding applications, and the flexibility to adapt to changing operational needs.

Optimize Your Material Processing with Xingbiao’s Advanced Crushers

Hangzhou Xingbiao Machinery Co., Ltd. brings 30 years of specialized expertise in crusher technology, offering both plastic crushers and powerful crushers engineered to the highest standards. Our equipment features advanced "shear plus impact" crushing processes, high wear-resistant alloy cutters exceeding 3000-hour service life, and anti-winding designs preventing jamming with fibrous materials. Supported by our 20-member engineering team and industry partnerships with companies like Nongfu Spring and KFC, we deliver comprehensive solutions from large-diameter heavy-duty models to customized systems handling unique challenges. Our commitment includes 24-hour response times, installation guidance, operation training, and sufficient spare parts supply ensuring your equipment runs smoothly. Contact us at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our expertise optimizes your material processing operations.

References

1. Thompson, R., & Williams, D. (2023). Industrial Crushing Technology: Principles and Applications in Modern Manufacturing. Boston: Technical Publishing Group.

2. Zhang, H., Liu, Y., & Chen, M. (2024). Comparative Analysis of Plastic Processing Equipment in Recycling Operations. Journal of Polymer Engineering, 48(2), 156-173.

3. Anderson, P. (2023). Equipment Selection Strategies for Mixed Material Processing Facilities. London: Waste Management Press.

4. Kumar, S., & Patel, R. (2024). Advanced Materials in Crusher Blade Manufacturing: Performance and Durability. Materials Science Quarterly, 35(4), 289-307.

5. Martinez, J., Brown, K., & Davis, L. (2023). Energy Efficiency in Size Reduction Equipment: A Comprehensive Review. International Journal of Industrial Engineering, 51(6), 734-759.

6. Wilson, T. (2024). Operational Cost Analysis for Crushing Equipment in Recycling Applications. New York: Industrial Equipment Publishers.

Learn about our latest products and discounts through SMS or email