- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose the Best Plastic Shredder for Industrial Applications?

Selecting the right plastic shredder for industrial applications can significantly impact your operation's efficiency, cost-effectiveness, and environmental sustainability. There are so many models and settings on the market today that it's important to know what makes good equipment different from average equipment so you can make a sensible buy. Not only can a good plastic shredder get rid of trash quickly, but it also makes recycling and resource recovery easier, which is ideal for circular economy projects. This complete guide will help you choose the appropriate tools for your business by covering everything you need to know, from the many types of shredders to how to compare their performance specs.

What Are the Main Types of Plastic Shredders Available for Industrial Use?

To choose the correct plastic shredder for your needs, you need to know about the numerous types that are available. There are a lot of different kinds of shredders on the industrial market, and each one is designed to handle a certain type of material and processing need. Single-shaft plastic shredders are great for shredding soft things like bags, films, and other soft things because they contain one spinning shaft with cutting knives that work against fixed blades. These machines are great for making particles of the same size since you can adjust the screens. They function best when you need to make something all the time. The design keeps noise and dust to a minimum, and the hydraulic pusher mechanism makes sure that the material flows smoothly. People desire to utilize single-shaft plastic shredders in places where there are strict environmental laws because of this.

Specialized Shredder Configurations

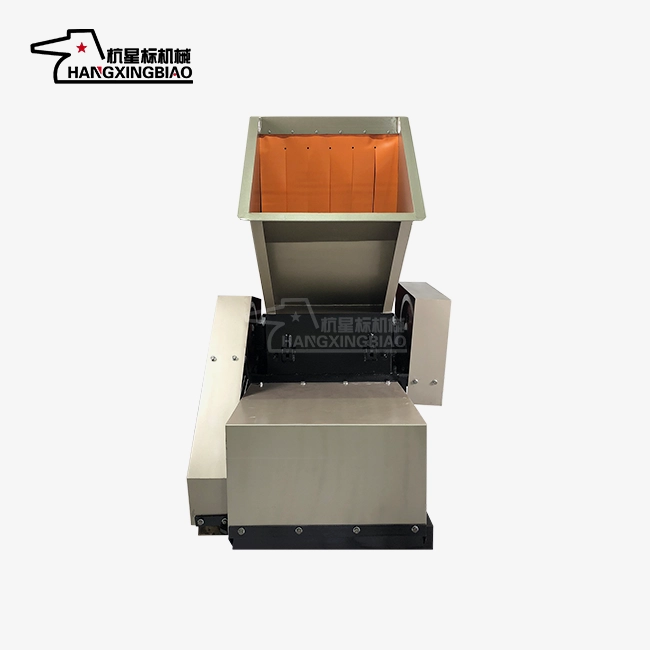

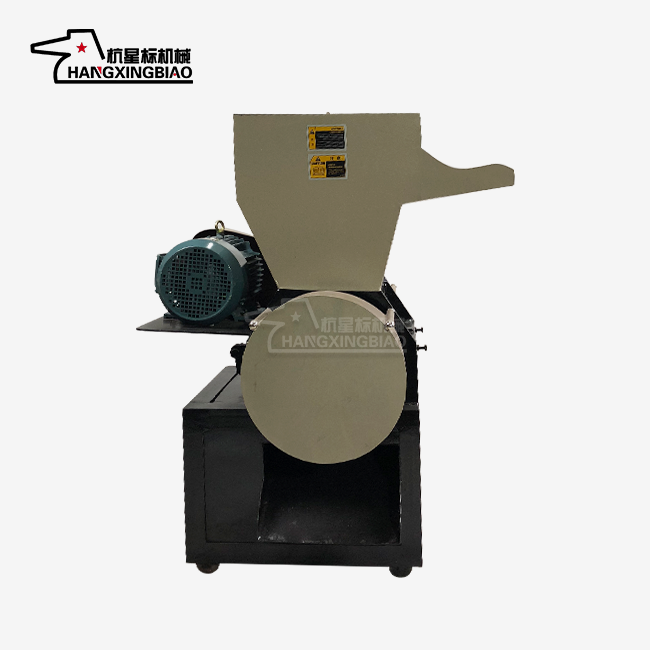

Beyond the usual shaft configurations, specialty plastic shredders meet distinct processing issues. Granulators use both shredding and grinding to make particles of the same size, which are great for regrinding in injection molding and extrusion operations. Hammer mill plastic shredders use swinging hammers to break down materials, which makes them great for fragile plastics and mixed waste streams because they can process a lot of them quickly. Horizontal pipe shredders have feed systems that are made just for them that can handle lengthy profiles and pipes without having to cut them first. This makes things easier for firms who work with linear plastic items.

Choosing Based on Material Characteristics

The physical properties of your input materials should guide your plastic shredder selection. Hard, stiff plastics like PVC pipes and HDPE containers need designs with high torque and reinforced cutting systems. Soft, flexible materials like films and woven bags need anti-wrapping features and knife spacing that is optimized. Double-shaft or four-shaft plastic shredders that can handle a wide range of materials without needing to be set up differently are great for mixed waste streams. If you know what your material is like, you can buy equipment that can process your specific feedstock quickly and easily.

Capacity and Throughput Considerations

The sort of plastic shredder that works best for your business depends a lot on how much you need to shred. For small to medium-sized businesses that process several hundred kg per hour, single-shaft machines are a good value and work well. Plastic shredders with two or four shafts can handle a lot of recycling at once, which is what high-volume recycling centers need. Matching the shredder's capacity to your real processing needs stops you from spending too much on extra features and keeps you from running into bottlenecks that slow down your work.

How Do You Determine the Right Capacity and Output Size for Your Plastic Shredder?

To figure out how much capacity a plastic shredder needs, you need to look at a number of related factors that have a direct impact on how well it works and how much money you can make. First, figure out how much garbage you currently make or process by evaluating both your daily and peak output rates. A facility that makes five tons of plastic garbage every eight-hour shift needs a plastic shredder that can handle at least 625 kilograms per hour. However, choosing equipment with 20–30% more capacity gives you more options and allows for future growth. Think about how the density of the material changes. Bulky goods take up more space but may process faster than dense, compact materials.

Material Flow and Feed System Design

No matter what the nameplate capacity ratings say, how well you feed the plastic shredder affects how much it can actually shred. Manual feeding procedures only reach 60–70% of their potential capacity because the materials are not always presented in the same way and the operator becomes tired. Automated feed systems that use conveyors, hoppers, or robotic loaders keep the flow of materials consistent, which improves cutting efficiency and gets close to rated capacity. The feed opening dimensions of the plastic shredder must be able to fit your biggest things without having to cut them down first, since chopping them down by hand takes more time and costs more money. Hydraulic pusher systems push stubborn materials through the cutting chamber with force, stopping bridging and keeping the flow of tough feedstocks steady.

Continuous Operation Versus Batch Processing

Your operational mode significantly affects capacity requirements and equipment selection. Continuous processing operations running multiple shifts daily need robust plastic shredders designed for sustained operation with minimal downtime. These uses need for high-end equipment with better cooling systems, stronger parts, and automatic monitoring functions. In batch processing settings where computers don't always have to be running, machines that are more versatile and less expensive can be used. The duty cycle rating of a plastic shredder shows how long it can run without stopping. Industrial machines usually have 100% duty cycles, whereas lightweight equipment is suited for short-term use.

What Key Features Should You Look for in a High-Quality Industrial Plastic Shredder?

Premium industrial plastic shredders stand out because they are built better, have more advanced engineering, and have more safety features that make sure they will work reliably for a long time. Heavy-duty steel fabrication is the first step in building the machine's structural basis. High-strength steel plates are welded together with precision and then treated to relieve stress so they don't bend when the machine is running. Good plastic shredders have thick-walled housings that hold the cutting forces in place while also reducing noise and vibration. This makes the work environment safer. Check the design of the cutting chamber to make sure the blades are spaced and shaped in the best way to cut efficiently while using the least amount of energy.

Safety and Operational Features

Comprehensive safety features protect operators while enabling efficient material processing. Quality plastic shredders incorporate interlocked access panels that immediately halt operation when opened, preventing contact with moving components. Emergency stop buttons positioned at multiple locations around the machine provide rapid shutdown capability when hazards arise. The hopper design should include safety bars or mesh screens preventing operators from reaching cutting chambers while allowing easy material loading. Dust extraction ports and optional collection systems maintain clean working environments by capturing airborne particles generated during shredding operations.

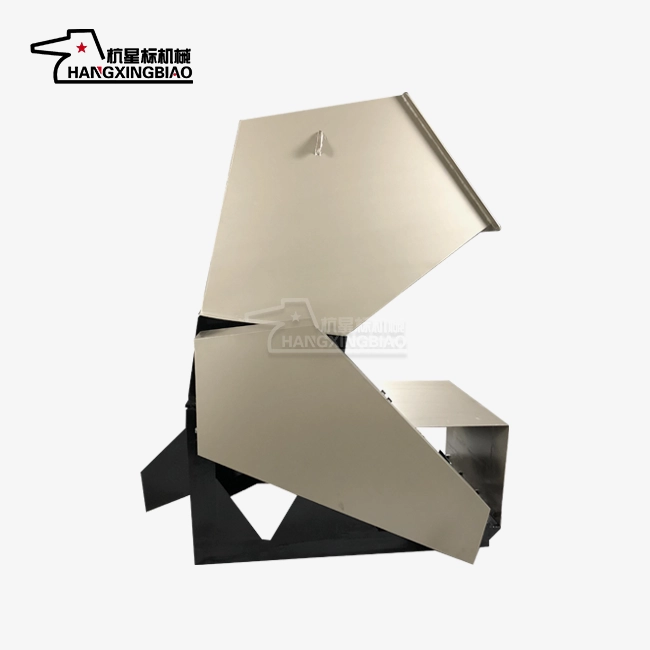

Maintenance Accessibility and Design

Thoughtful maintenance design reduces downtime and extends equipment life. Superior plastic shredders feature hinged access panels that swing open for quick blade inspection and cleaning without requiring complete disassembly. Clear service markers that indicate when maintenance is necessary should be placed in conveniently accessible locations near lubrication points. Rapid switching between particle size parameters should be possible using the screen mounting system's tool-free removal and installation capabilities. Detailed user manuals that include parts diagrams, maintenance schedules, and troubleshooting instructions guarantee that your staff can do routine maintenance effectively.

Versatility and Adaptability

Modern factories need equipment that can adapt to many types of materials without needing a lot of reconfiguring. The greatest plastic shredders can handle a wide range of materials since they have adjustable parts and extra accessories. Interchangeable rotor designs let you select between processing procedures that work best for different types of plastic. Magnetic separators can be added to cutting systems to safeguard them when they are processing polluted feedstock that contains iron. The plastic shredder platform should be able to be upgraded and expanded so that your initial investment continues to be useful as your needs change over time.

Conclusion

Selecting the optimal plastic shredder for industrial applications requires careful evaluation of your specific processing needs, material characteristics, and operational requirements. You may make a smart purchase that gives you consistent performance and good returns by learning about the many types of shredders, figuring out the right capacity and output specs, and putting quality features first. Keep in mind that better equipment with smarter controls, stronger construction, and more advanced blade technology is cheaper over time, even though it costs more up front.

Hangzhou Xingbiao Machinery Co., Ltd. is ready to assist you discover the best plastic shredder for your needs. We have 30 years of specialized experience and a full range of products, from standard crushers to custom systems. Our equipment breaks the usual single-material limit. Our high-tech machines can quickly process a wide range of materials, including plastics, rubber, wood, and foam. They can also make particles that are 2mm or larger by changing the screens. With our 20-person technical staff, connections with other companies, and full after-sales support that includes 24-hour response times, we make sure your business works smoothly. Contact us at mailto:postmaster@xingbiaocrusher.com to discuss your requirements and discover how our expertise can optimize your material processing operations.

FAQ

Q: What factors should I consider when selecting an industrial plastic shredder?

A: Key factors include material type, required capacity, desired output size, and operating mode. You should also assess construction quality, safety features, and maintenance accessibility to ensure reliable long-term performance.

Q: What are the main differences between single-shaft and double-shaft plastic shredders?

A: Single-shaft shredders are ideal for soft materials like films and bags, offering uniform particle sizes. Double-shaft models handle tougher, mixed, or bulky plastics with higher torque and throughput, making them suitable for large-scale recycling operations.

Q: How can I determine the right capacity for my plastic shredding operation?

A: Estimate your daily and peak waste volumes, then select a shredder with 20–30% extra capacity to accommodate growth. Consider material density, feed consistency, and whether your operation runs continuously or in batches.

Q: What maintenance practices help extend a plastic shredder’s service life?

A: Regular lubrication, timely blade inspection and replacement, and keeping feed materials clean and consistent prevent wear and blockages. Using equipment with easy-access panels and tool-free screen changes further reduces downtime.

Q: Why should you use Hangzhou Xingbiao Machinery Co., Ltd. for your shredding needs?

A: Xingbiao Machinery has been in business for 30 years and uses advanced "shear plus impact" technology. They also work with top manufacturers to make shredding systems that can be customized and last a long time. They also offer complete engineering support and 24-hour after-sales service.

References

1. Miller, J., & Thompson, R. (2023). Industrial Shredding Technologies: Design Principles and Applications. New York: Manufacturing Press.

2. Chen, L., Wang, H., & Zhang, Y. (2024). Advanced Materials Processing in Plastic Recycling Industry. Journal of Industrial Engineering, 45(3), 234-251.

3. Anderson, K. (2022). Equipment Selection for Waste Management Facilities. London: Environmental Technology Publishers.

4. Rodriguez, M., & Kumar, S. (2023). Mechanical Size Reduction Systems: Theory and Practice. Berlin: Technical Engineering Press.

5. Williams, D., Brown, A., & Davis, C. (2024). Sustainable Manufacturing Through Efficient Material Processing. International Journal of Production Research, 62(8), 1567-1589.

6. Lee, J., & Park, S. (2023). Optimization Strategies for Industrial Shredding Operations. Tokyo: Asian Manufacturing Institute Publications.

Learn about our latest products and discounts through SMS or email