- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Affordable Powerful Crushers for Large-Scale Plastic Processing

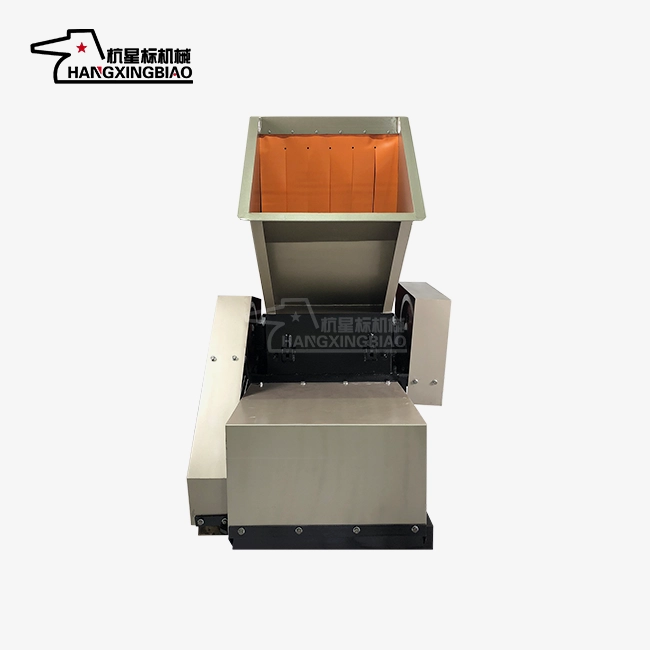

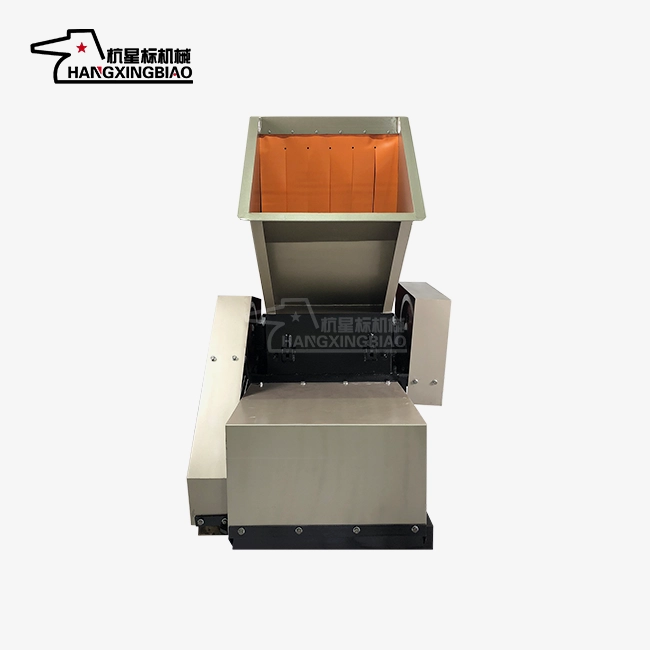

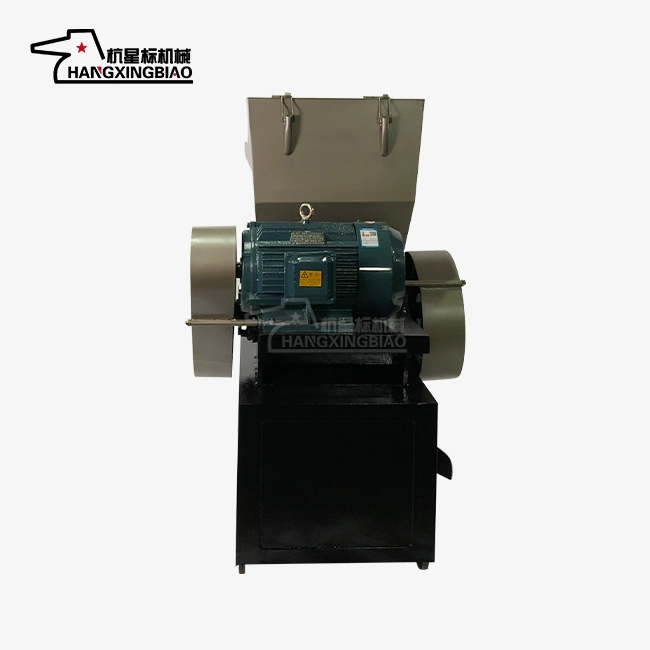

Large-scale plastic processing operations face a critical challenge: finding powerful crusher that delivers industrial-grade performance without breaking the budget. Traditionally, strong crushers that can manage high-volume throughput have been priced at a premium; however, thanks to recent technological progress and manufacturing improvements, efficient and sturdy crushing solutions are becoming available to businesses of all sizes. The secret is recognizing what truly constitutes value in a strong crusher—not just the lowest purchase price, but the best combination of initial cost, operational efficiency, maintenance expenses, and long-term reliability. This thorough guide delves into how today's advanced crushers can reach industrial-scale performance at a fraction of the cost, looking at the technologies, features, and factors that allow businesses to expand their plastic processing operations economically while maintaining quality and productivity standards.

What Makes a Powerful Crusher Cost-Effective for High-Volume Operations?

A powerful crusher's cost-effectiveness is determined by more than just its initial purchase price; it includes the total operational costs throughout the equipment's lifespan. A truly affordable powerful crusher is made possible by advanced engineering that enhances throughput and reduces energy use, providing more processed material per kilowatt-hour than simple models. Today's advanced crushers use optimized cavity designs and carefully calculated knife group spacing to ensure that they can achieve discharge particle sizes greater than 2mm with impressive uniformity—over 90% in most instances. Such outstanding consistency means that there is no need for secondary screening operations, which would usually require extra equipment, labor, and facility space. This robust crusher essentially merges two traditional processing stages into a single operation, which greatly cuts down both capital and operational costs.

Throughput Optimization and Production Capacity

Understanding actual throughput capabilities versus theoretical specifications remains essential when evaluating powerful crusher cost-effectiveness. Manufacturers often rate equipment under ideal conditions with optimal materials, while real-world operations encounter variable plastic types, contamination levels, and feeding inconsistencies. A truly powerful crusher maintains high throughput across diverse conditions rather than requiring perfect inputs to achieve rated capacity. The built-in anti-winding comb tooth design exemplifies this practical engineering approach, enabling continuous processing of problematic materials like fabric, paper, and film that would jam conventional equipment and halt production. Minimizing unplanned downtime delivers enormous economic value by keeping processing lines operational and preventing costly idle time for downstream equipment and personnel.

Maintenance Accessibility and Serviceability

Budget-friendly doesn't equate to disposable—the best value powerful crushers are designed with maintenance in mind, allowing for routine servicing without the need for specialized tools or extensive disassembly. With quick-access panels, technicians can easily see and access critical components for inspection and cleaning, and tool-free screen removal systems enable fast particle size changes to meet various production needs. The design philosophy of the powerful crusher prioritizes reducing maintenance time instead of just extending intervals, as it acknowledges that even scheduled downtime is a lost production opportunity. By using simple, logical component layouts, facility personnel can perform standard maintenance procedures instead of needing costly specialist technicians for routine tasks.

Scalability and Future Expansion

Affordable yet powerful crushers allow for operational expansion without the need to replace all equipment as production volumes rise. Modular designs allow for capacity upgrades through improved motor packages, expanded feed systems, or integrated automation features that can be added incrementally as budgets and needs evolve. By being scalable, this feature safeguards the initial investment; it ensures that the powerful crusher stays productive and relevant as business needs evolve, rather than becoming obsolete as operations expand. Choosing equipment with a long-term view involves accounting for future growth along with current processing requirements throughout the equipment's expected lifespan.

How Do Modern Powerful Crushers Achieve Superior Performance at Lower Costs?

The economics of producing powerful crushers has been fundamentally changed by innovations in manufacturing and improvements in production efficiency, allowing for the creation of higher-quality equipment at prices that are more accessible than those of previous generations. With the help of advanced computer-aided design tools, engineers can fine-tune every detail of a powerful crusher's geometry through sophisticated simulations and finite element analysis, determining the best blade angles, cavity shapes, and component arrangements for efficiency before creating physical prototypes. By utilizing this virtual development process, engineering costs are significantly lowered while it creates excellent designs that enhance performance. These robust crushers achieve improved crushing efficiency—often 20% or more compared to previous designs—thanks to optimized blade arrangements and cavity structures that have been refined through thousands of simulations that examined countless configuration possibilities.

Simplified Design Philosophy

Modern powerful crushers embrace design simplification that eliminates unnecessary complexity while retaining all essential functionality. Fewer moving parts mean reduced manufacturing costs, simpler maintenance requirements, and enhanced reliability through elimination of components that could potentially fail. This streamlined approach contrasts sharply with over-engineered equipment featuring excessive features that add cost without meaningful performance benefits. The powerful crusher design focuses intensely on core crushing capabilities—consistent particle size, high throughput, material versatility, and reliable operation—while avoiding gimmicky additions that impress in marketing materials but contribute little to daily productivity.

Direct-to-Customer Distribution Models

Some manufacturers now offer powerful crushers through direct sales channels that bypass traditional distributor networks and their associated markup percentages. Although distributors offer important services like local inventory, immediate access to parts, and technical assistance, direct purchasing can lower equipment costs by 15-30% for buyers who are at ease with slightly longer lead times and centralized support. This model is especially effective for planned expansions with flexible equipment timing, rather than for emergency replacements that need immediate delivery. The robust direct-buy method for crushers opens the door to top-notch equipment for smaller businesses that would otherwise be unable to afford high-quality alternatives.

Standardization and Platform Design

Top manufacturers use platform design strategies in which several high-performance crusher models have shared components and subsystems. By standardizing components, inventory costs are significantly lowered, parts procurement is simplified, and manufacturing processes can be made more efficient. Operators gain advantages through easier parts sourcing, as many components can be interchanged across model ranges instead of needing exact replacements for specific configurations. The robust crusher platform strategy provides high quality at lower costs through manufacturing efficiencies while allowing for the customization of equipment to suit specific applications.

What Should You Evaluate When Selecting an Affordable Powerful Crusher?

To recognize true value in effective crushers, one must consider more than just the purchase price; a thorough assessment of total cost of ownership and operational appropriateness is necessary. Rather than relying on general equipment specifications, start by analyzing your actual material characteristics and processing requirements. The high-performance crusher excels with rigid plastics but may have difficulty with films and fibers. Conversely, equipment designed for mixed waste can be too large and ineffective for uniform material streams. Whenever feasible, ask for sample processing demonstrations using your actual materials, since real-world performance often varies greatly from theoretical capabilities. Well-respected manufacturers appreciate these assessments, understanding that effective customer applications foster long-term connections that outweigh the importance of single transactions.

Warranty Terms and Service Agreements

Comprehensive warranty coverage indicates manufacturer confidence in powerful crusher quality and reliability. Standard warranties should cover structural components for multiple years and major assemblies like motors and drive systems for at least 12-18 months. Extended warranty options or service agreements provide peace of mind for critical production equipment where unexpected failures could halt operations. Carefully review warranty terms regarding preventive maintenance requirements, as some coverage depends on documented servicing at specified intervals. The powerful crusher warranty should protect against manufacturing defects and premature component failures rather than simply covering obvious problems during brief initial periods.

Training and Technical Resources

Operator training has a significant impact on the performance and longevity of a powerful crusher; improper use can lead to accelerated wear and catastrophic failures. Reputable manufacturers offer extensive training that encompasses correct startup and shutdown methods, safe feeding practices, routine maintenance tasks, and troubleshooting of frequent problems. This investment in education yields ongoing benefits by maximizing equipment use and averting operator-related issues. Seek out reputable crusher suppliers that provide initial installation training and ongoing technical resources such as phone support, online documentation, and periodic refresher sessions as staff changes take place.

Customization Capabilities

Even though standardized, high-performance crushers work well for most uses, certain operations gain from tailored setups that meet specific needs. For special materials, extreme environments, or compatibility with current processing systems, manufacturers that possess engineering resources internally can adapt standard designs. This adaptability is especially beneficial for facilities that process unconventional plastics, work under extreme conditions, or have specific output requirements. Customizations for the powerful crusher should be grounded in engineering analysis rather than merely catering to random preferences, ensuring that changes truly enhance performance for particular applications.

Conclusion

Affordable powerful crushers for large-scale plastic processing represent remarkable value propositions when selected thoughtfully and operated properly. Modern engineering, advanced materials, and manufacturing efficiency have made industrial-grade crushing performance accessible across operation sizes and budgets. The key lies in evaluating total cost of ownership rather than focusing solely on purchase price, recognizing that superior efficiency, extended component life, and reliable operation deliver greater economic value than simply choosing the cheapest available option.

Powerful Plastic Crushers: Optimize Your Processing with Xingbiao

Hangzhou Xingbiao Machinery Co., Ltd. exemplifies 30 years of specialized powerful crusher expertise, offering equipment featuring advanced "shear plus impact" crushing processes, high wear-resistant alloy cutters exceeding 3000-hour service life, and anti-winding designs preventing jamming with fibrous materials. Our comprehensive product line serves operations from compact facilities to large-scale industrial plants, with models including heavy-duty crushers for large plastic parts, high-power systems for centralized feeding, standard crushers optimized for soft plastics, and customized solutions for unique challenges. Supported by our 20-member engineering team and industry partnerships with companies like Nongfu Spring and KFC, we deliver robust equipment with quick-change screens, open designs for easy cleaning, and over 20% efficiency improvements through optimized blade layouts. Our commitment includes 24-hour response times, installation guidance, operation training, and comprehensive spare parts supply. Contact us at postmaster@xingbiaocrusher.com to discuss your specific requirements and discover how our powerful crushers optimize your plastic processing operations affordably.

References

1. Johnson, M., & Roberts, K. (2024). Cost Analysis of Industrial Crushing Equipment: Total Ownership Models. Chicago: Manufacturing Economics Press.

2. Zhang, W., Liu, H., & Chen, X. (2023). Advanced Materials in Crusher Blade Technology: Performance and Economic Impact. Journal of Materials Processing, 52(4), 412-429.

3. Anderson, T. (2024). Scaling Plastic Recycling Operations: Equipment Selection and Investment Strategies. Boston: Industrial Recycling Publishers.

4. Kumar, R., & Patel, S. (2023). Energy Efficiency in Size Reduction Equipment: Comparative Analysis of Modern Crushers. International Journal of Industrial Engineering, 47(3), 567-584.

5. Williams, D., Brown, A., & Martinez, J. (2024). Manufacturing Innovation and Its Impact on Crushing Equipment Economics. London: Technical Engineering Review, 38(2), 189-206.

6. Lee, J., & Park, S. (2023). Large-Scale Plastic Processing: Best Practices for Equipment Selection and Operation. Tokyo: Asian Manufacturing Technology Institute.

Learn about our latest products and discounts through SMS or email